The company maintains a high commitment to on going r d efforts and provides a complete portfolio of products ranging from composites to high reliability thermal management hsd and rf ptfe laminate materials.

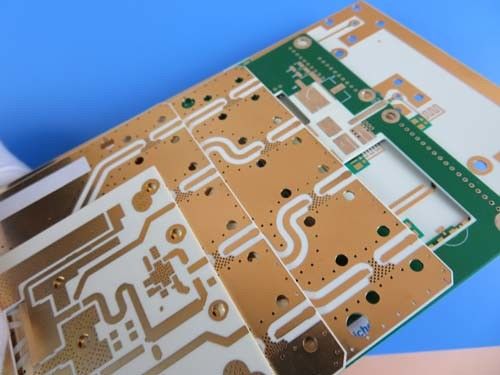

Thin pcb laminate.

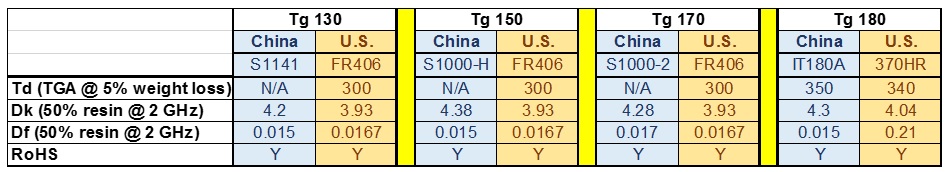

Ptfe microwave laminates are one of the most used laminates for pcb lamination.

Sytech is a world leader in the development and production of laminates.

The thin laminate active devices worked as designed radiated emi improved signal noise reduced.

Based in dongguan since 1985 shengyi technology co ltd.

These features are ideal printed circuit boards which are used in applications comprising radio frequencies.

With a dielectric thickness of 9 3 or 3 5 mils this new high frequency material is designed specifically for use as the rf portion of multilayer pcb assemblies and in thin circuit applications.

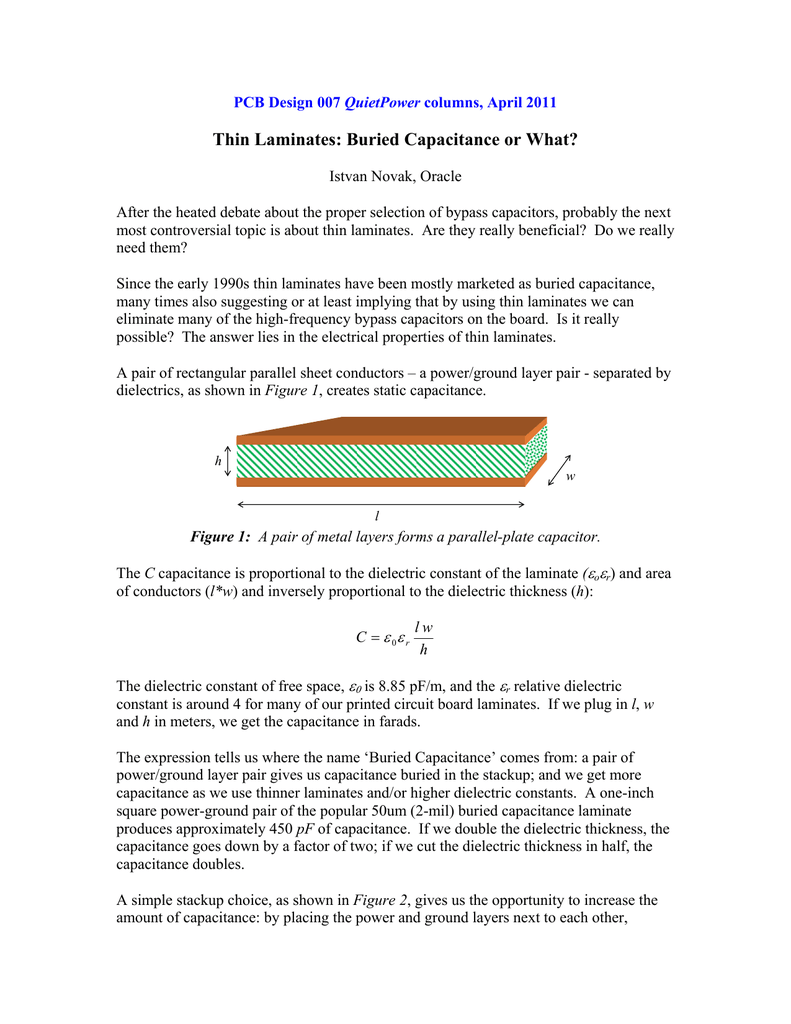

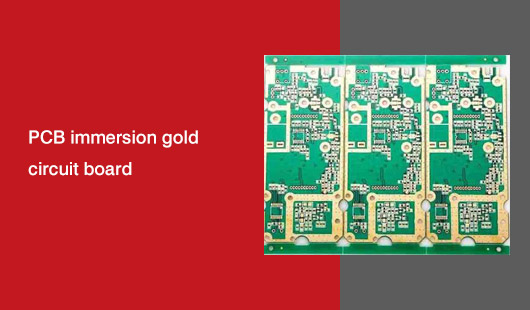

Dupont interra thin copper clad laminates are specifically designed for use as embedded capacitance materials in multilayer rigid printed circuit boards.

They offer the best mechanical strength reliability and capacitance stability on the market.

By utilizing interra laminates between the power and ground planes in a power distribution network pdn designers can reduce the modal resonances and lower the inductance between the power and ground planes.

As this blog detailed some years ago thinner printed circuit board pcb laminates offer many electrical benefits as well as mechanical advantages compared to thicker circuit materials especially at higher frequencies reaching into millimeter wave bands.

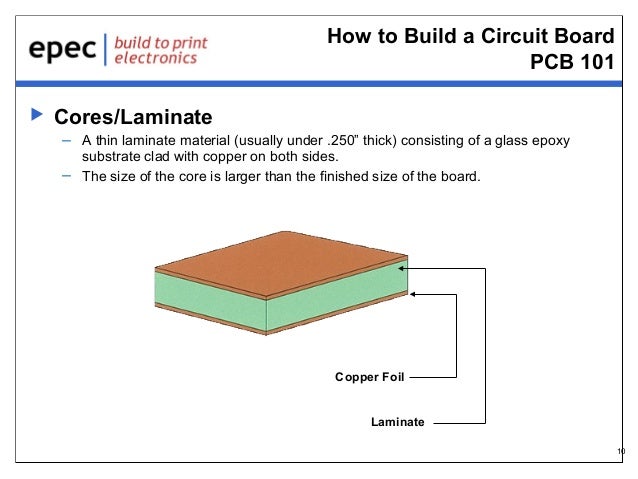

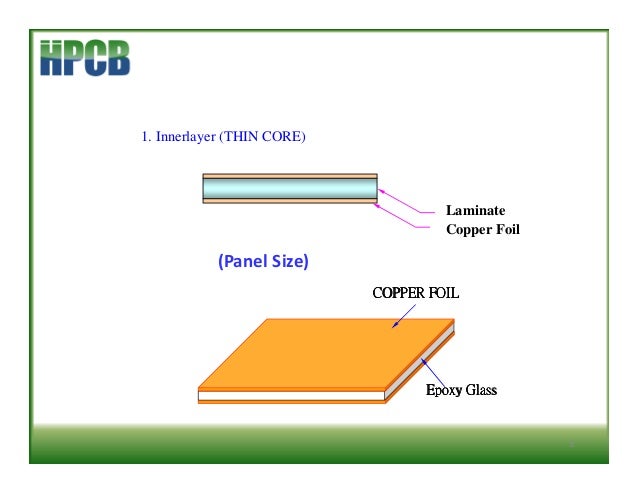

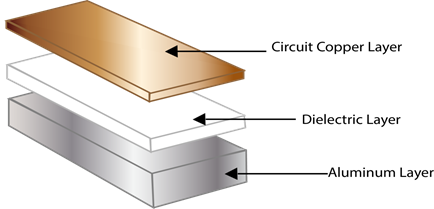

Laminates sometimes called copper clad laminates are composed of sheets of prepreg that are laminated together with heat and pressure with sheets of copper foil on either side.

These laminates offer significantly improved electrical performance over standard fr4 and often a combination of fr4 and a high speed laminate may be preferable to an alternative fr4 material.

Fr4 tends to have higher losses than other printed circuit board pcb materials that are specialized for rf applications.

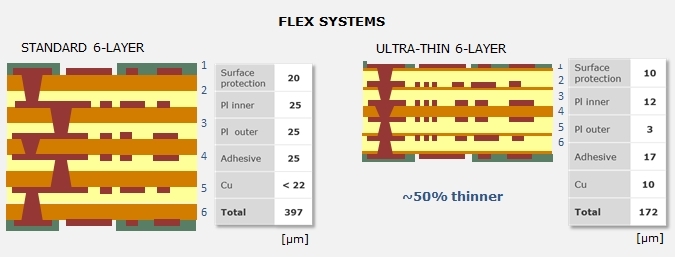

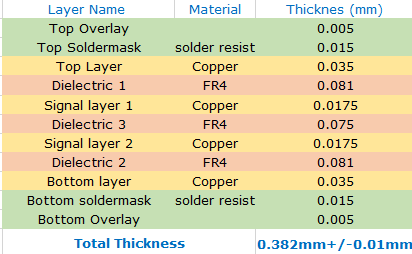

For 4l pcb thickness will be more about 0 6mm.

Normal thickness of pcb is from 1 0 mm to 2 0 mm and the min thickness is 0 3 mm or 0 4 mm 1l or 2l.

Teflon ptfe microwave laminates.

The epoxy resin ccl having a thickness excluding copper foil thickness of less than 0 8 mm is generally referred to as the thin board ipc standard is 0 5 mm.

Thin can be a good thing for high frequency circuit laminate materials.

Once the resin hardens pcb laminates are like a plastic composite with sheets of copper foil on both sides.

This type of board always named as thin pcb or thin board.

The reasons for this are it has consistent dielectric constant very low electrical loss and tight thickness tolerance.

According to the thickness of the copper clad laminate it can be divided into conventional board and thin board.

This extra thin printed circuit means the thickness of printed circuit board is more thin than normal pcb.