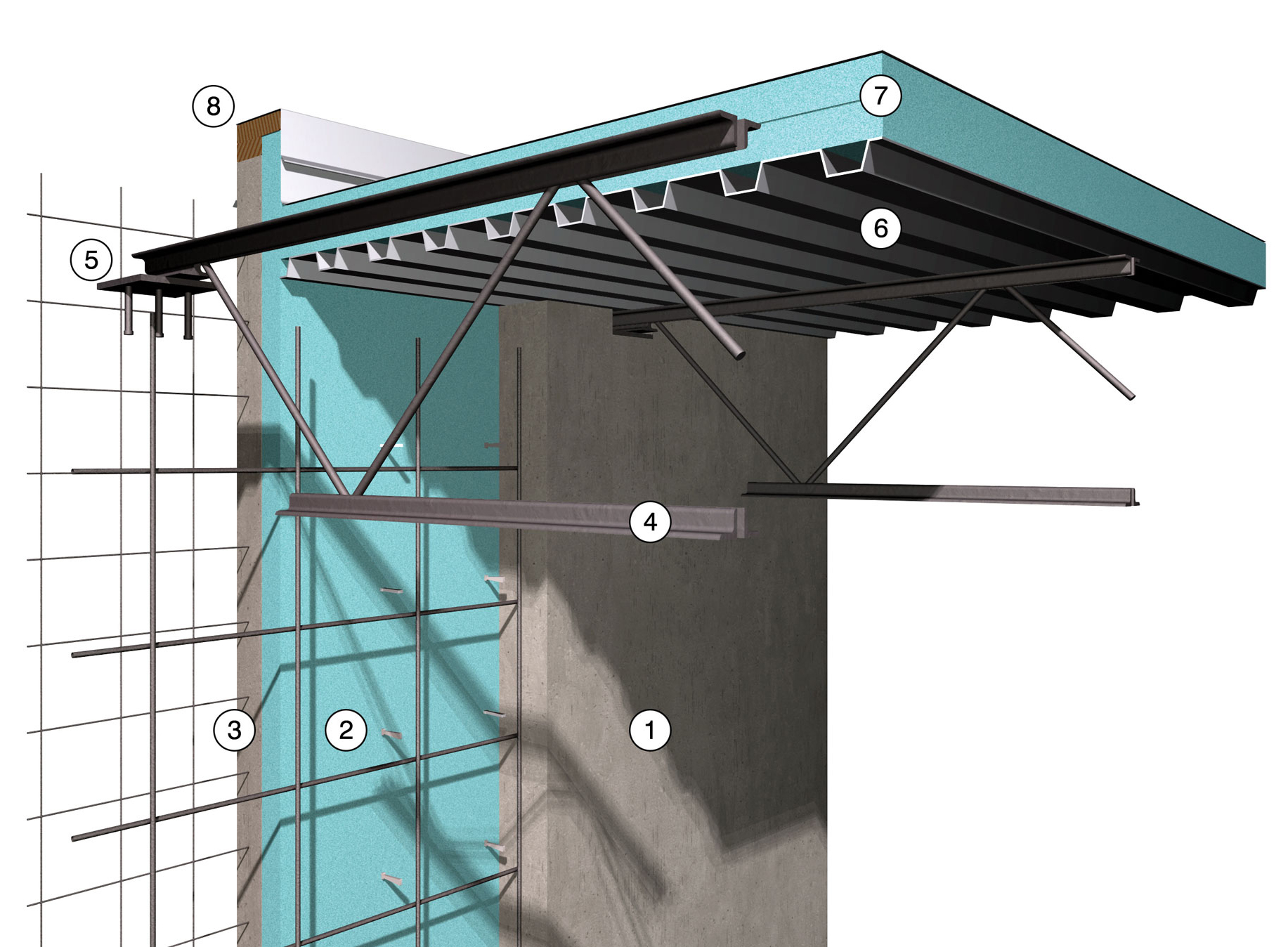

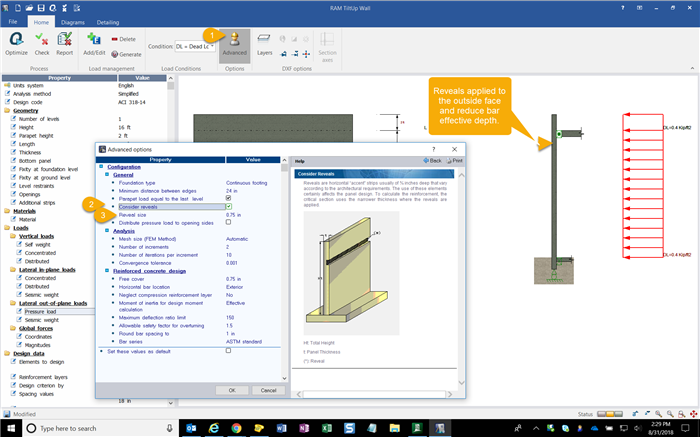

Tilt up wall panel analysis and design spwall software spwall is a program for the analysis and design of reinforced concrete shear walls tilt up walls precast walls and insulate concrete form icf walls.

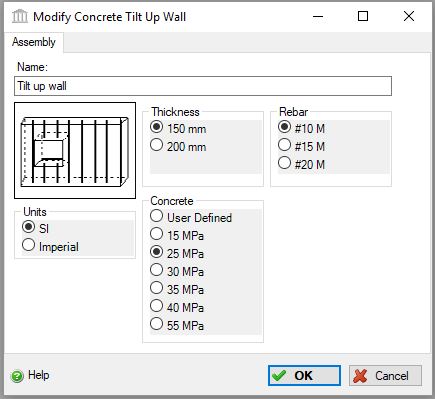

Thicknesses of tilt up concrete walls.

The panels are limited to 12 feet wide for shipping but the contractor doesn t have to mess around with them.

And second it reduces the weight by replacing.

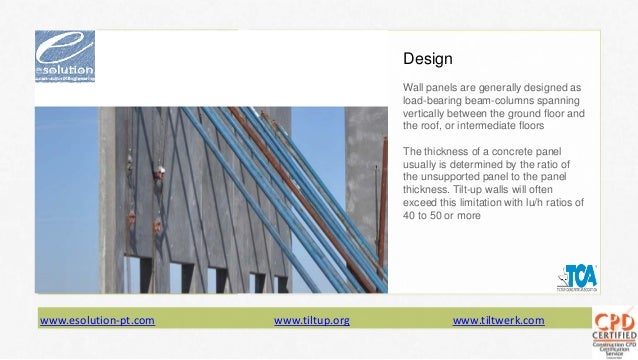

The thickness of a concrete panel usually is determined by a quantity called the slenderness ratio.

For instance a 6 x is 5 1 2 inches tall so start with 5 1 2 inch thick tilt up.

It is common to use extruded polystyrene at 2 to 6 inches thick.

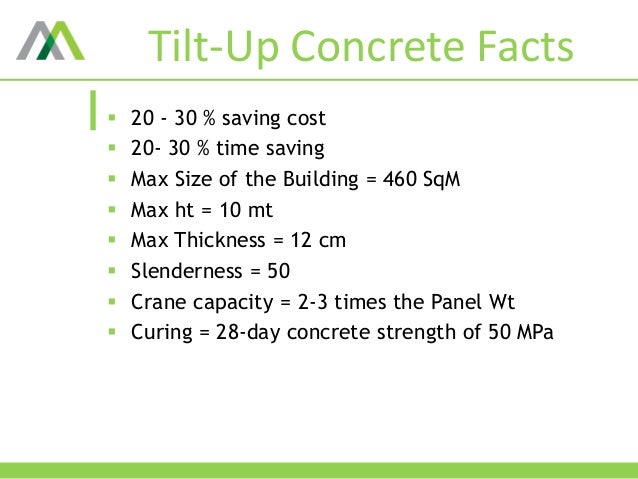

What is the minimum size building that is economical.

Some as small as 5 000 square feet can be economical if they are relatively tall.

This one two punch delivers new buildings quickly and economically which might explain why more than 650 million square feet of tilt up buildings go up every year.

Walls can range from r values of about 2 for uninsulated panels up to about 32 for walls containing thicker layers of insulation.

O6 guide to tilt up design and construction 1 1general tilt up is a form of construction ideally suited to the rapid realisation of a wide range of buildings for industrial commercial residential and community use.

This form is lightweight in two ways.

The panel itself is usually between 5 inches or 7 inches thick.

The wall is adequate with 16 6 vertical reinforcement and 6 25 in.

Tilt deck is a lightweight form used to create reinforced concrete walls.

Tilt up tilt slab or tilt wall is a type of building and a construction technique using concrete though it is a cost effective technique with a shorter completion time poor performance in earthquakes has mandated significant seismic retrofit requirements in older buildings.

The minimum thickness for commercial walls is generally 5 inches with 7 inches the most typical thickness reinforced with 1 3 to 2 5 psf of reinforcing.

Tilt up construction combines the strength and durability of reinforced concrete with the precision and efficiency of the design build methodology.

Also another approach that worked out well is factory made tilt up.

However keep in mind that these can be as little as a few inches thick.

The use of the form system for tilt up walls is applied since 2004 and marketed under the name of tilt deck.

An insulated panel is much thicker as the exterior panel is up to 3 inches the insulation is 2 to 4 inches and the interior wall could be 5 to 10 inches thick.

The generally accepted slenderness ratio on tilt up walls is 50.

What is the typical thickness of a tilt up concrete panel.

It provides the benefits of solid concrete walled buildings quickly and economically.

This is the ratio of the unsupported panel height usually the distance between the floor slab and the roof stru c t u r e attachment to the panel thickness.