We specifically formulate these alloys to maximize properties such as low temperature toughness abrasion resistance low extractability chemical resistance ultimate elongation and hot melt strength.

Thermoplastic vinyl nitrile.

Besides vinyl latex and nitrile gloves two new kinds of gloves have begun to grow in popularity.

Auroraflex sbs and sebs compounds utilize multiple tpe tpr chemistries to impart high performance properties for durability and easy processing.

Timco rubber designs and provides custom flexible and rigid tpe parts for companies in need of quality products for their applications.

Learn about the differences between each kind of glove what they have in common and some of their benefits in today s post.

It is lightweight and has good abrasion resistance good tear strength weather resistance and electrical properties.

Our wide range of tpe s combine many of the performance properties of thermoset rubber with the processing ease of plastic thereby providing design options and greater cost reduction opportunities.

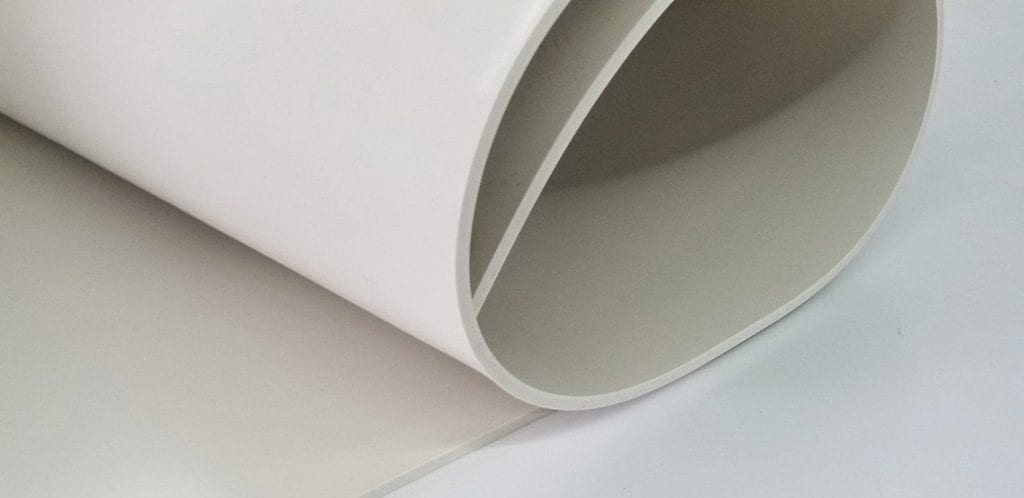

The formal definition of a thermoplastic rubber or elastomer tpe is a polymer blend or compound which above its melt temperature exhibits a thermoplastic character that enables it to be shaped into a fabricated article and which within it s design temperature range possesses elastomeric behaviour without cross linking during fabrication.

Nitrile tpe thermoplastic elastomers aurora plastics offers a complete line of nitrile tpes.

Rm biltrite tuff trac vinyl matting is manufactured from a proprietary blend of new and recycled materials.

Cpe gloves 101 what cpe gloves are made of.

About thermoplastic rubber tpr tpr material also known as thermoplastic rubber is a material that has properties of both plastic and rubber.

This mixture is specifically engineered to provide superior performance and durability.

Cast polyethylene cpe gloves and thermoplastic elastomer tpe gloves.

Standard pvc is blended with thermoplastic polyurethane nitrile rubber eva and other polymers for enhanced performance qualities.

Tpe options are available as low as 10a up to 50d durometer hardness.

Tpr performs similarly to vulcanized rubber and is reusable and recyclable.