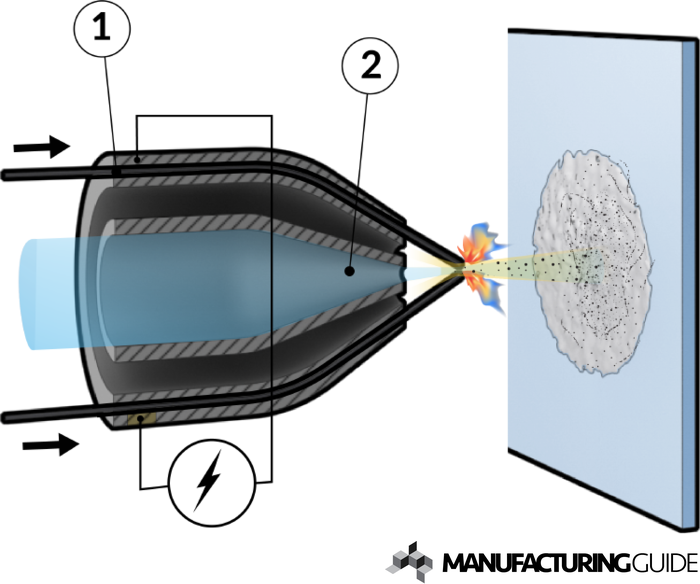

Thermal spraying is an industrial coating process that consists of a heat source flame or other and a coating material in a powder or wire form which is literally melted into tiny droplets and sprayed onto surfaces at high velocity.

Thermal spray zinc coating.

Zinc thermal spraying is an alternative coating solution that protects steel from erosion saving time and money.

A zinc thermal spray is a way to apply a zinc coating to a substrate material.

A zinc thermal spray uses the thermal spraying process to adhere the zinc to the base material as opposed to hot dip galvanizing electrogalvanizing or other methods of galvanizing.

The hot zinc thermal spraying process is an anti corrosive protection system used for very long life coating requirements.

The adhesion strength of zinc coatings on ptfe and pe improved by pre heating the polymer substrates prior to thermal spraying.

Arc spray also.

What is thermal spray coating.

Zinc spray coatings help protect base materials from corrosion.

Aluminum and zinc coatings about 260 20 µm thick were successfully deposited on ptfe using wire arc spray spraying.

Thermal spraying is particularly suited to protecting articles which are too large to be dipped in galvanizing baths as the coating can reach structures that are already installed.

As a result flame sprayed zinc coatings are much purer than those applied by hot dip galvanizing for instance since the molten zinc used in galvanizing picks up considerable iron because of the nature of the process.

Bradley s use modern thermal arcspray technology for spraying pure zinc metal wire.

The zinc 15 aluminum thermal spray coating was introduced in the late 1970 s and is about the highest aluminum composition in zinc that can be industrially made into wire.

In this thermal spray process the zinc wire is melted atomised and sprayed in molten form onto the blasted substrate to create a rich.